Real Life is 3D: Now Printing is Too!

Real Life is 3D: Now Printing is Too! - Rossland High School Education (sevensummitslearning.com)

"A CD. How quaint. We have these in museums."- Eoin Colfer.

Step aside, George Jetson, one of today's newest technological marvels, 3D printing, is coming to Rossland.

This printing machine uses software and imagination to create the unimaginable with prepared precision.

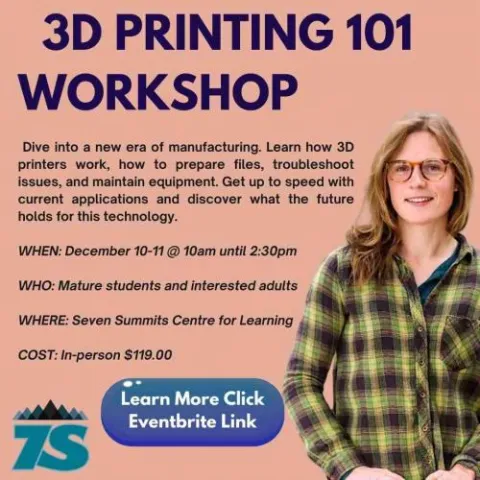

December 3rd is 3D printing day. To celebrate, Kailey Allan is hosting an introductory course at Seven Summits Centre for Learning on December 10th and 11th. Allan teaches full-time for the Digital Fabrication and Design program at Selkirk College in Trail, BC.

"3D printers are more accessible than ever. For $350, you can get a quality machine. Elementary schools are even starting to adopt 3D printing, which means the software has gotten very user-friendly. Open-source design files from websites like Thingiverse don't require you to have any design skills, either. You can download and print other people's designs. However, 3D printing unlocks an entirely new capability when you learn to design custom parts that are specific to your needs. Of course, like any machine, they have quirks, so you need to know how to fix and maintain them," says Allen, the 3D workshop facilitator.

"This technology promises to solve some major challenges facing society today. For example, the medical industry uses 3D printing for complex surgical pre-planning, tool creation, and prosthetics. Invisalign has revolutionized dental care with its invisible, custom 3D-printed braces. Twente Manufacturing, located in Procter, is 3D printing concrete which promises to reduce construction waste and time. Other industries include furniture, fashion, aviation, automobile, prop making, and many others," adds Allen.

3D printing is unique because there are ways only to print what is needed and produce zero waste compared to other manufacturing methods. In addition, 3D printing is less time-consuming than one may think, as items often print unsupervised overnight. Polylactic Acid (PLA) is the most common material; it is a corn-based biodegradable material. "Even now, and into the future, companies will be looking for people with trained skills in this technology," Allan asserts.

"I don't think our issue is about making too much plastic. Our issue is that we throw too much of it in the landfill," says Allan, "Our reason for this is because the things we buy stop serving our needs, so we throw them out. Things are also poorly designed for recyclability or serviceability. That broken TV remote control might still work, but we can't replace the cracked housing, for example. Many things end up in landfill simply because they are poorly designed. So, the issue is not necessarily rooted in plastic but rather in the poor design of everyday objects. 3D printing can help solve these problems and reduce waste because it allows us to personalize and highly customize the items needed. Biodegradable materials are important, but simply put, the best way to keep things out of landfills is to never put them there in the first place. I believe 3D printing and better design offer this benefit to the user."

Like any emerging technology, the earlier one embraces learning it, the better. 3D printing is the wave of the future available to Rosslanders now. "Access to this information is available, and I hope Rosslanders will embrace the learning behind this skill set. As a hobby or source of employment, the opportunities are limitless,"says Allen.

Training on this technology is the next in the long line of the many inventions and innovations of the past that Rossland was the first to be known for pioneering. "It has never been easier for people to learn to 3D print," acknowledges Allan. "The accessibility is much more available, and trained personnel are highly sought after for employment opportunities."

Interested to know what you will learn? Allan continues. "This introductory workshop will have participants working to prepare and design files to create a planter made from PLA material, a corn-based bioplastic. By the end, they will take home their own 3D printed part. The point is to get people to try this new technology and show them how easy it is to adopt it into their everyday life. For students, this is a critical skill that looks great on a resume. All they need is a laptop with software and to sign up for the course on December 10th and 11th."

For further information, and pictures, and to sign up, follow the Event Brite link 3D Printing 101 Workshop in Rossland, BC Tickets, Sat, 10 Dec 2022 at 10:00 AM | Eventbrite |